The Heatle revolution, heating with German ingenuity

Heatle's story is more than just a tale of technological innovation. It's a testament to resilience, precision, and the relentless pursuit of revolutionizing induction technology.

-

-

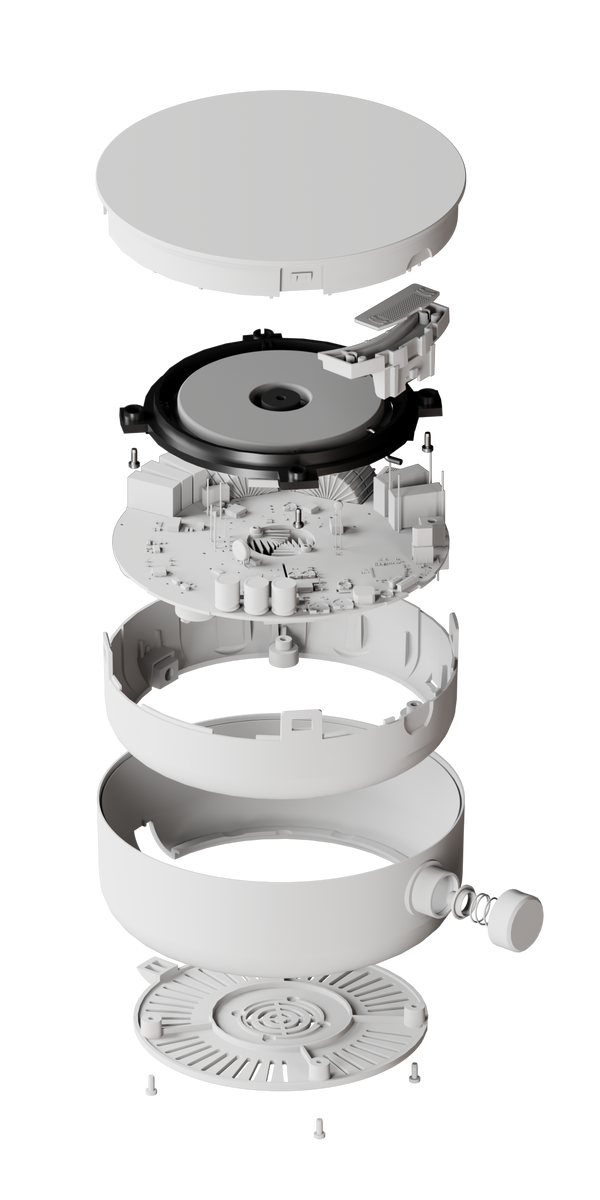

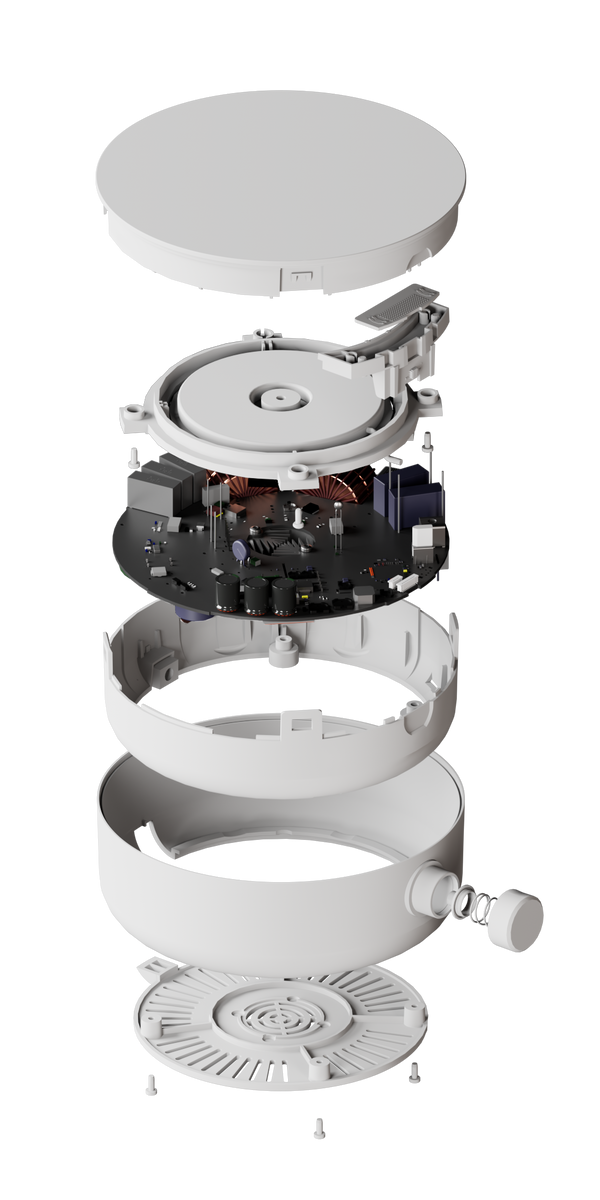

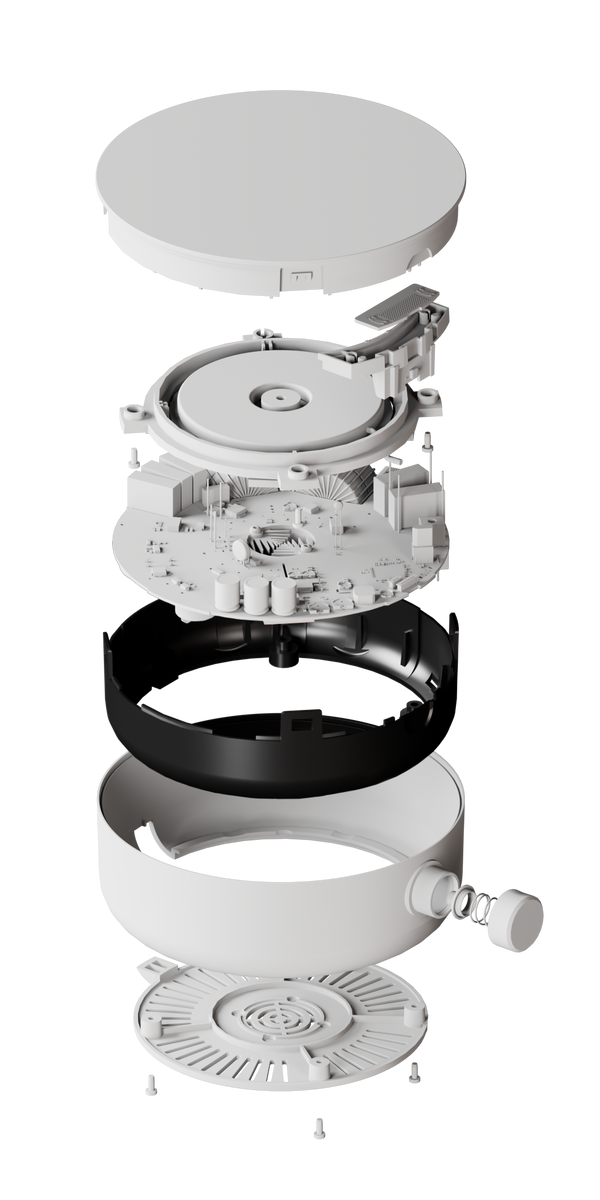

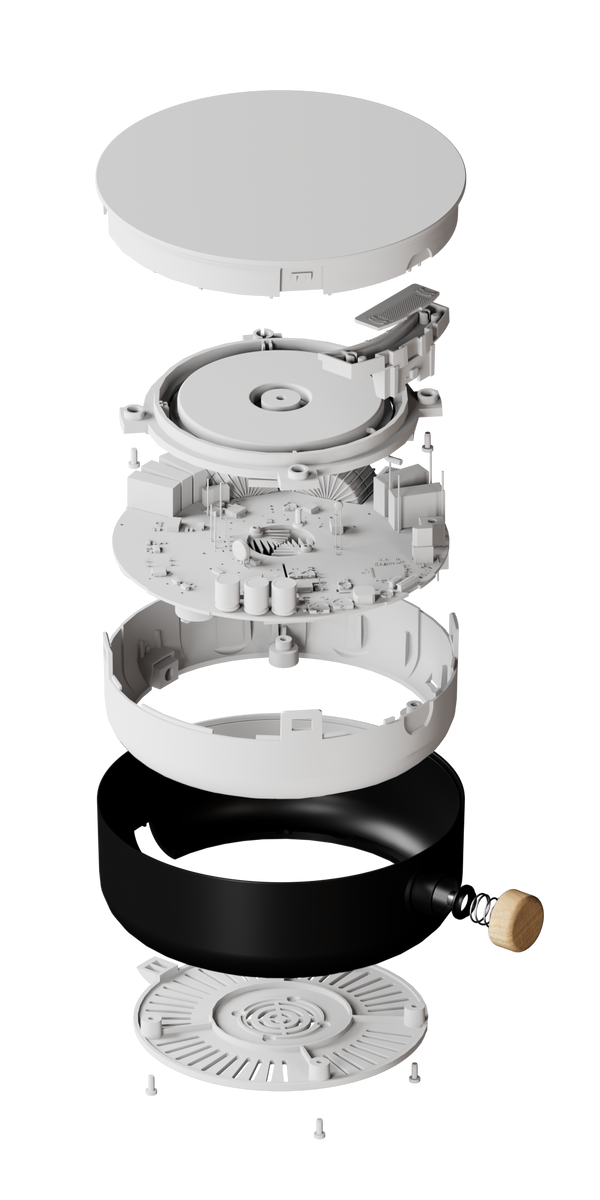

Device information

- Temperature: 30 - 100 °

- Capacity: 50 - 1000 ml

- Material: Oak, stainless steel

- Voltage: 220 - 240v

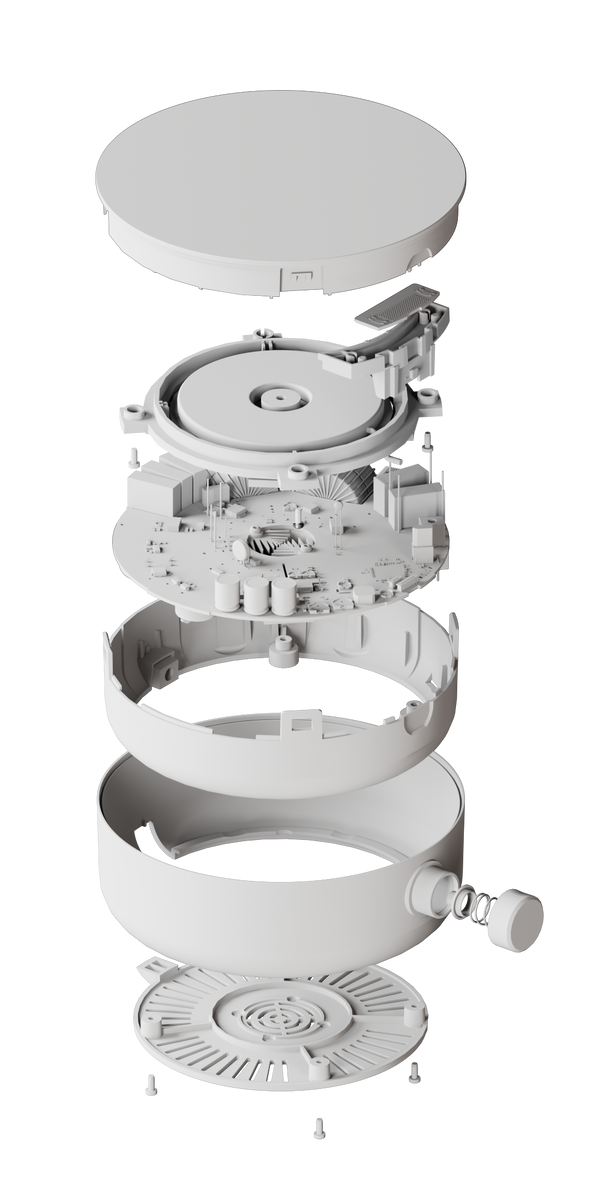

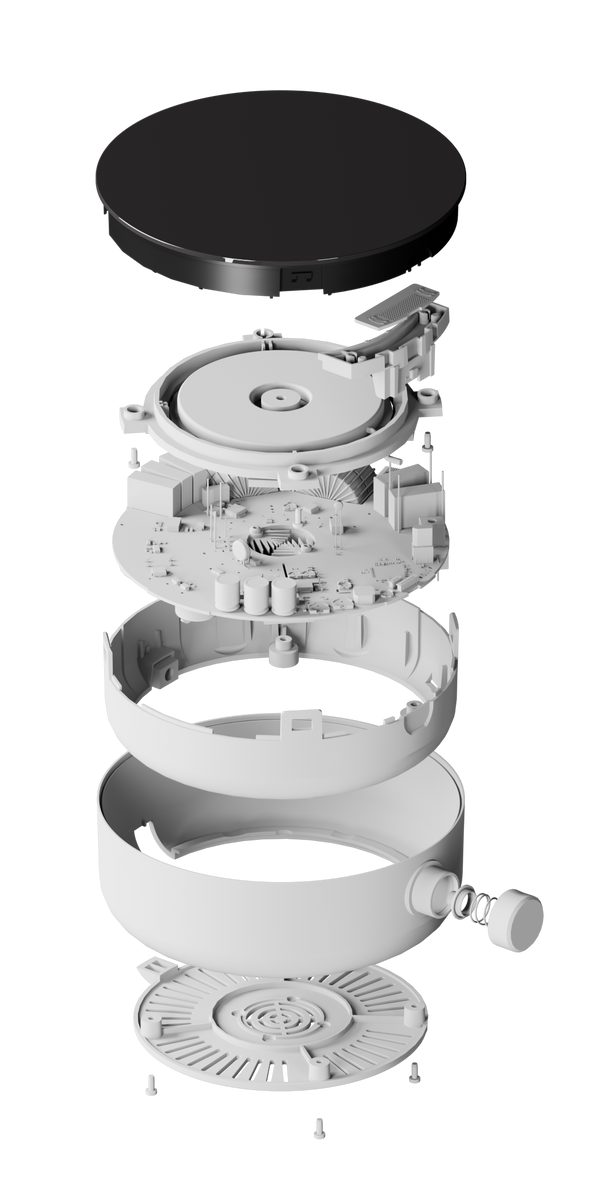

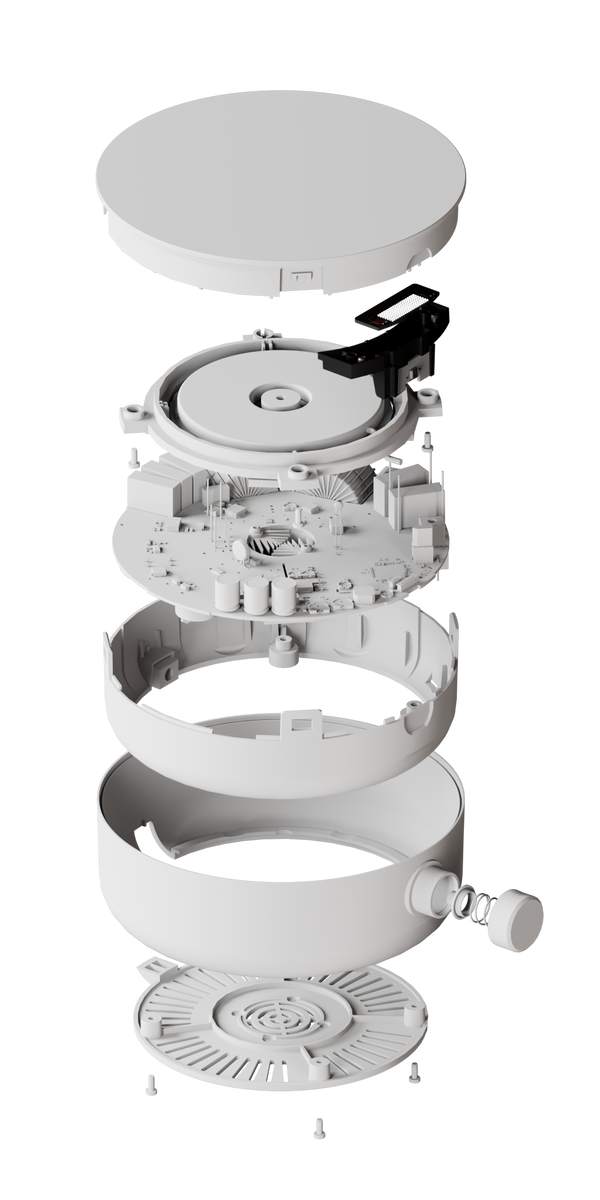

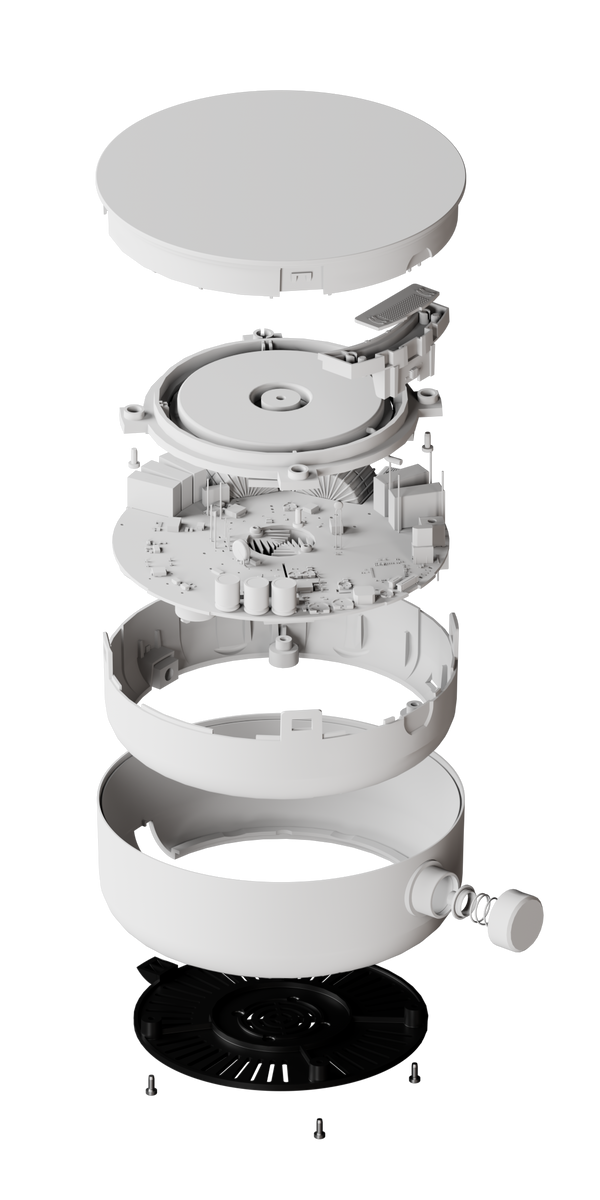

The magic of induction

The concept is simple yet revolutionary: combine a special metal disc with the efficiency and energy of induction, and voilá: the revolutionary magic of rapid heating

-

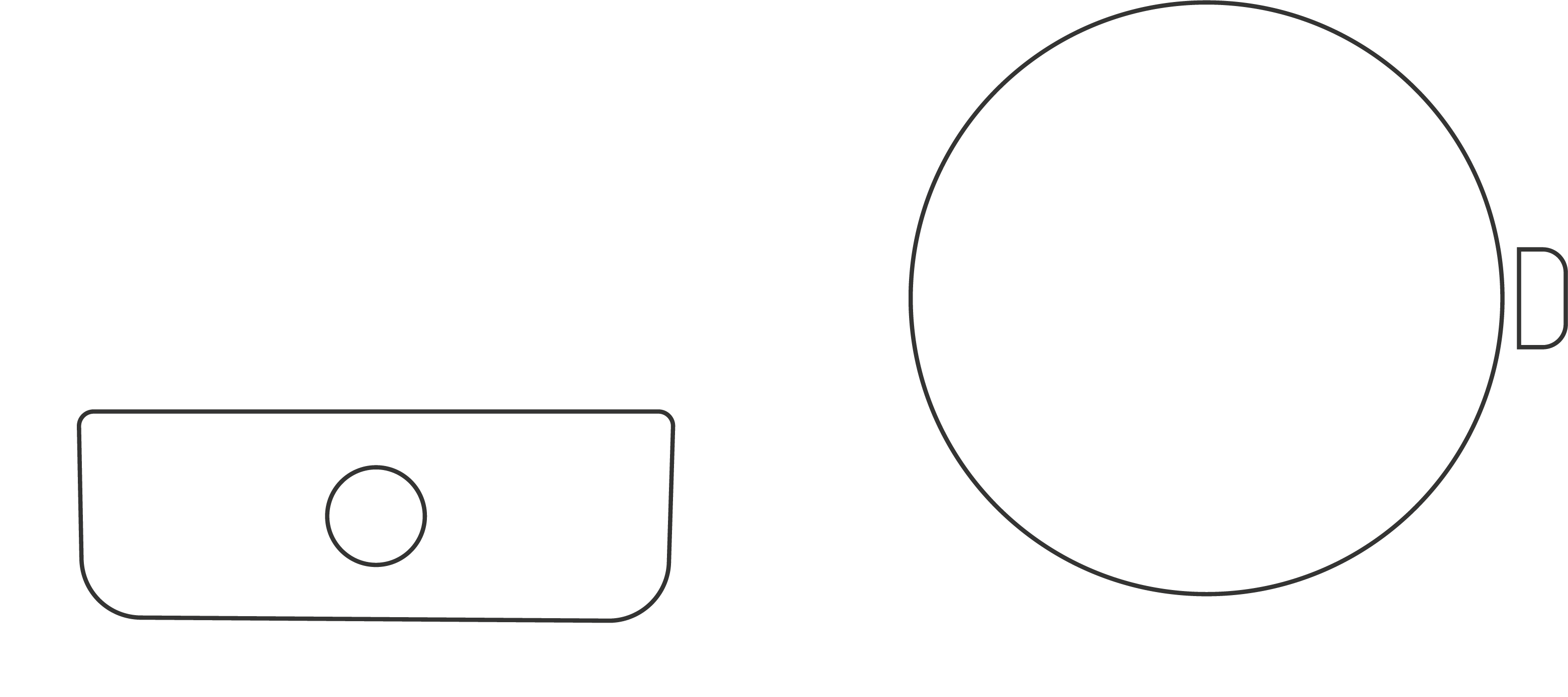

The Heatle rod

This stick with a smart sensor communicates with the Heatle via Bluetooth. It tells the device when your drink is ready. Place it in the cup for the heating to start.

-

The Heatle disc

Via the magnetic metal disc, your drink heats up. It connects to the device and transfers the heat directly into your cup.